Keeping your machinery in good condition in order to last a long time takes a lot of maintenance. Throughout your machine's lifetime, it can experience a great deal of wear and tear. Preventative care will help you to catch any problems with your machines before they become detrimental. However, it can be challenging to determine the best preventative care methods and remain aware of ideal opportunities for investing in upkeep. For instance, according to Quality Magazine, shopfloors should be kept at a constant 68 degrees Fahrenheit temperature. Without that knowledge, you're not setting yourself up for success. Here are more ways to ensure the conditions of your shop are optimal for your equipment.

Keeping Machines Clean

It's vital to the functionality of your machines to keep them clean. You don't want debris and build-up to affect the performance of your equipment. Unclean machines can also be a safety hazard. You can't subject any employees to work in less-than-ideal conditions. Create a safety plan to keep your machines free of excess oils. Provide the best conditions for your equipment by keeping it clean.

Regular Inspections

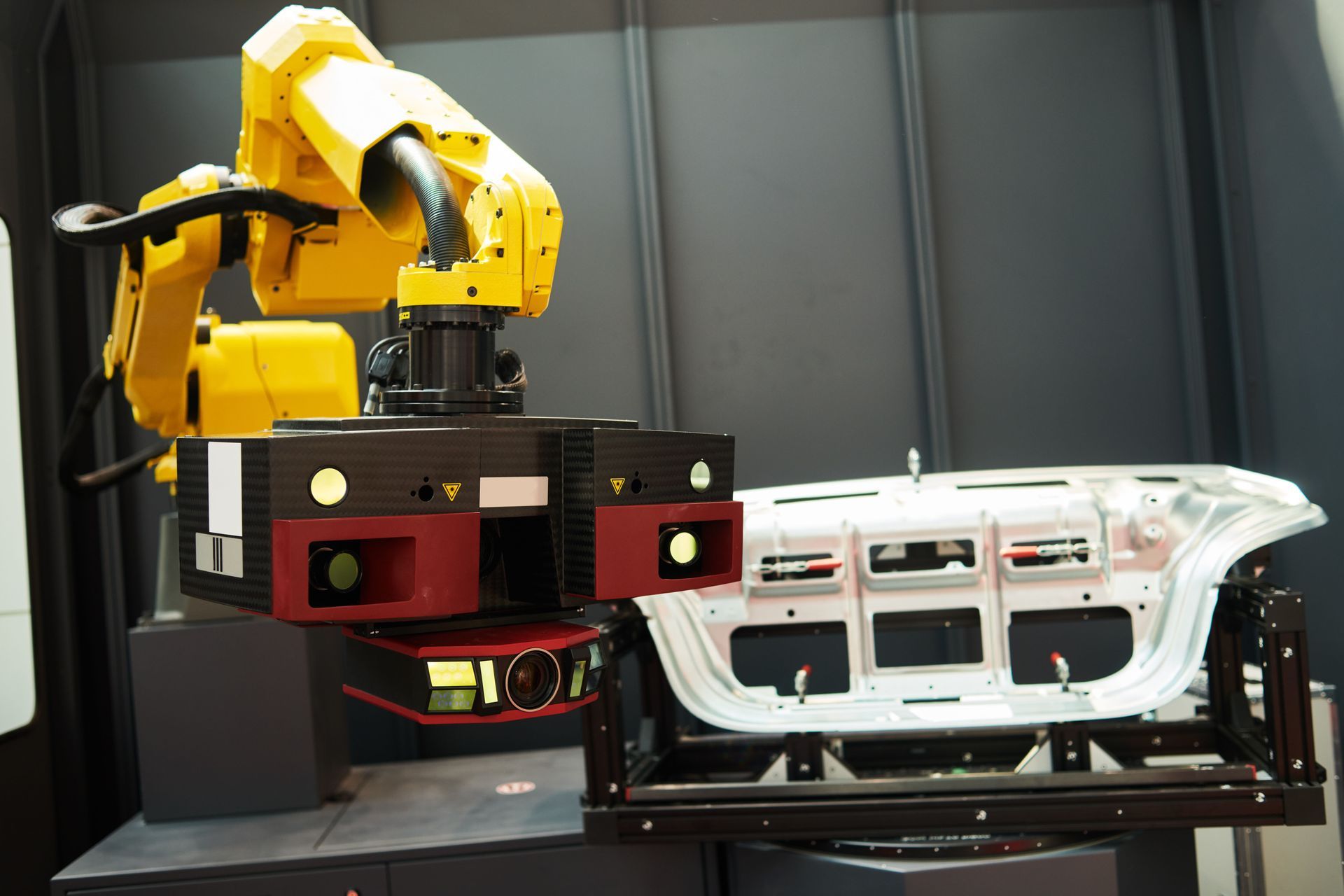

When taking care of your machines,

shopfloor metrology is important. Shopfloor metrology refers to performing measurements for inspection in a shopfloor environment. Create a plan to prepare your shop for regular machinery inspections. Working with a maintenance service that'll perform inspections will help you to keep up to date on which parts might be wearing out or need repairs. Shopfloor metrology will help you to keep your machinery healthy.

Replacing Parts When Needed

You should replace worn-out or damaged parts as soon as you become aware. You should be able to keep up with which parts need replacing through regular inspections. You can work with a maintenance professional to help you determine which parts are on their way out and which require immediate attention. It would be best if you didn't let the parts on your equipment wear out so much that they break or cause serious damage.

Ensuring that your shop provides the best conditions for your machinery will improve the productivity of your business. Functional equipment is vital to your success. You should take the time to maintain your equipment properly to get the longest possible use out of it. Contact Raytech Measuring Systems Inc today for all your shopfloor metrology needs.

Share On: